Current Custom Bach Project, begin date: 02-08-03

Only the "Z" braces left to go, then we'll be finished with the soldering!

One point I think I should make is about the amount of pressure or force used when assembling a horn. If all the parts are fitted prior to soldering, there doesn't have to be any tension added to the parts. The soldering jig here is tightened only enough to hold the bell to the valve casing. The "Z" braces will be soldered with absolutely no tension whatsoever, as they will be individually fitted and shaped.

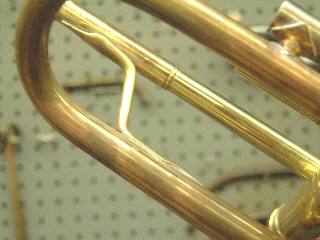

The first brace looks nice!

Now comes the second "Z" brace. Many people have experimented with the location of this brace. Both Vincent Bach and Eldon Benge considered this an important brace. One reason I prefer the larger flanged style braces is you tend to get more of the "sweet" area. See, with a smaller brace, you'd have to move it around quite a bit to find the right spot where the horn resonates and responds the best. The larger flanged brace seems to do the trick quicker. For the location of this brace, I copied my other horn (the horn this one is being patterned after) because I like the way it plays.

Excess solder will be carefully scraped and removed, then the brace area will be buffed. With lacquered horns, the clean-up phase of the assembly of a horn really shows. I think that is perhaps why we see so many of the cheaper brand horns going all silver plated - the plating covers up the poor soldering!